Impact strength is the ability of a material to withstand a sudden load applied to it without rupturing. It is measured in terms of how much energy the material absorbs before rupture.

High impact strength enables a product to avoid damage and rupturing from external and internal impact.

In the CPVC piping system, impact strength is a reliable benchmark used to determine superior product performance, longer service life, and low risk of damage during transportation and after implementation.

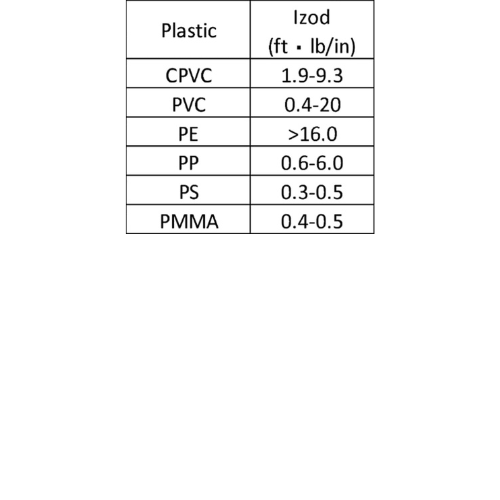

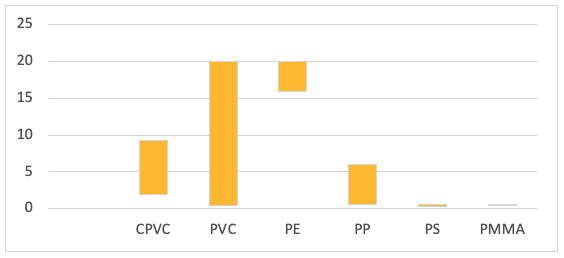

The chart below shows the typical impact strength for each type of plastic based on compound formulations. We can increase impact strength using the SEKISUI CPVC compound formulation technology.

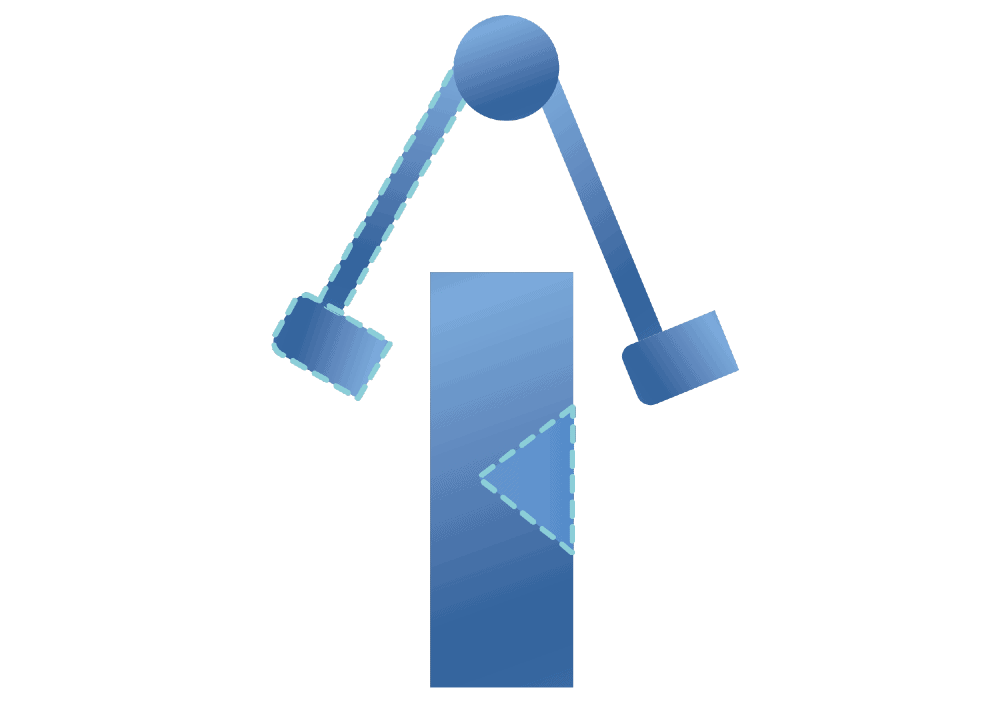

Impact strength is a material’s ability to withstand a suddenly applied mechanical load. Impact strength tests commonly consist of Charpy and IZOD specimen configuration.

The main difference between the IZOD and Charpy impact tests is the position of the specimen and type of notches.

Set the sample under the machine and rotate the hammer to the swing position. In the IZOD test, the specimen is positioned vertically with the notch facing the hammer. In the Charpy test, the specimen is positioned horizontally with the notch facing away from the hammer.

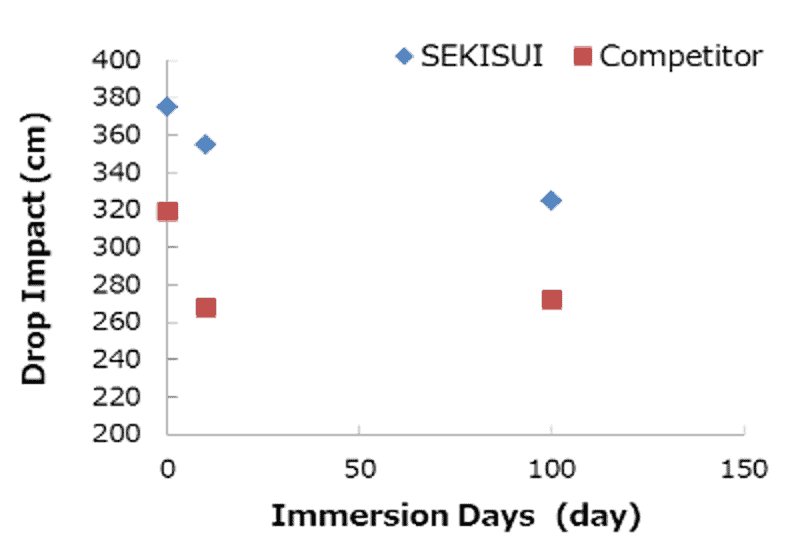

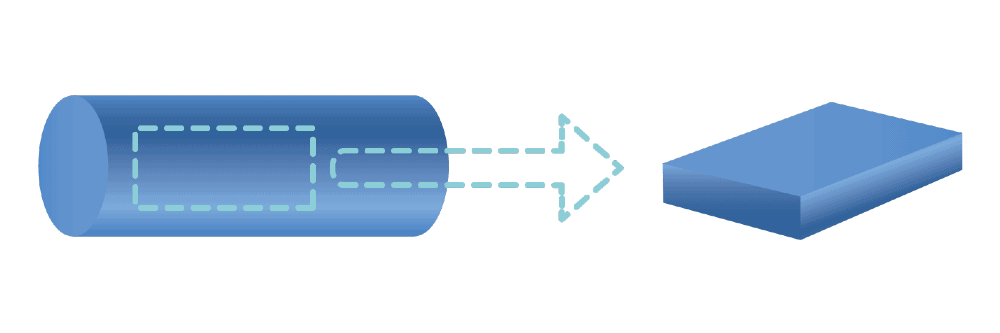

Drop impact strength measures a material’s ability to withstand external damage, such as damage that occurs during transportation or from falling or being dropped at a jobsite.

“Durastream” has high impact resistance. Its performance does not decrease even from long-term use at high temperatures.