- Language

- English

- 日本語

- English (India)

- हिन्दी

- 中文

SEKISUI CHEMICAL Group has led the industry as a pioneer in the PVC field.

In particular, we have gained a global market share in the CPVC business. Behind this is our solid technological strength, which is based on the thoughts behind our company name, “SEKISUI.”

The origin of the word “SEKISUI” is from a line in Sun Tzu’s book, The Art of War: “The victor’s battle is fought with such force that it is like cutting a full volume of water (i.e. Sekisui) into a deep valley.” For us, the “full volume of water” here is the technology we have accumulated over the years.

For related pages on SEKISUI’s Technology, click here

We have been working on the CPVC business with pride in the Sekisui name. The CPVC compound “Durastream” is the result of our accumulated technology. Today, “Durastream” is highly regarded worldwide for its high quality and reliability, but it has been a long road to the present day.

Since its foundation in 1947, SEKISUI has been consistently developed PVC and CPVC and has accumulated its technology. 1964 saw the establishment of Tokuyama SEKISUI Kogyo, establishing a production base in the raw materials field that has continued to the present day. Furthermore, in 2013, a state-of-the-art plant was established in Thailand to meet the growing global demand for CPVC, leading to the establishment of a stable production system.

For related pages on History of CPVC Business at SEKISUI, click here

Behind the “Durastream” brand lies the spirit of SEKISUI’s uncompromising technological research and Japanese manufacturing culture.

Sekisui Chemical sells the CPVC compound “Durastream” series.

In addition to sales, we also provide technical support in the field of molding to our customers, the molding manufacturers.

This is possible because Sekisui Chemical is also a pipe manufacturer itself and possesses high technical capabilities in the field of molding, such as extrusion and injection.

We contribute to improving our customers’ productivity through the following three approaches.

The quality of CPVC is determined by how evenly and at a high level the resin is post-chlorinated. CPVC produced based on Sekisui’s high development and technical capabilities has achieved the production of CPVC with excellent quality, with the entire resin being evenly and at a high level chlorinated.

This proprietary technology is one of the reasons why the Sekisui Chemical Group has gained a global share in the CPVC field.

In addition to providing CPVC compounds to customers according to their specifications, we also offer optimal formulations based on resins with high thermal stability, in response to customer requests and calculated backwards from the application and performance requirements of the customer’s end product.

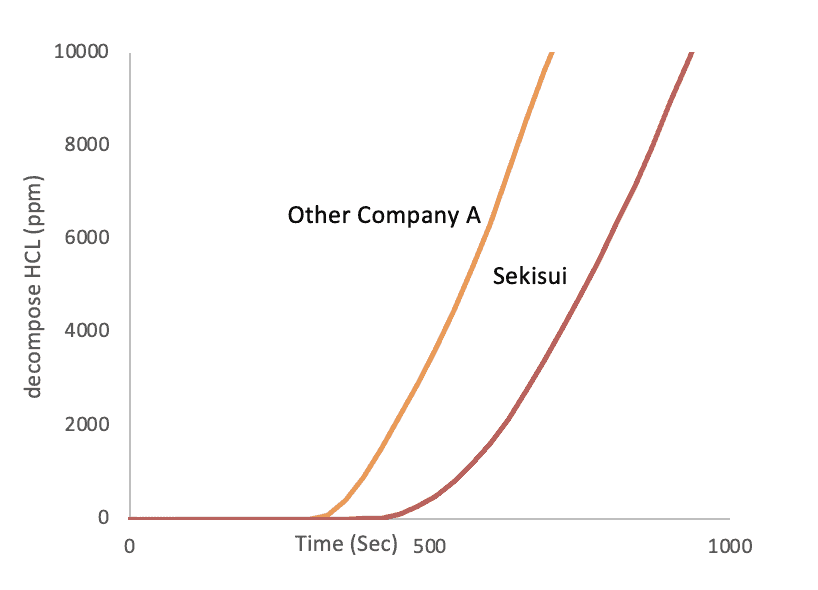

When using Sekisui’s CPVC compound “Durastream” for molding, it delays the dehydrochlorination that occurs over time. As a result, the product is less likely to burn, and high productivity can be expected.

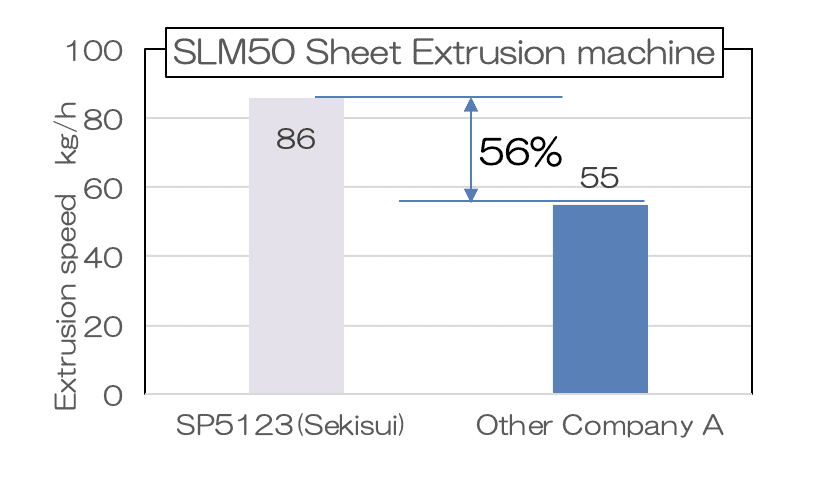

By using the CPVC compound “Durastream”, customers can achieve high production speeds. This makes it possible to reduce production time and costs.

Sekisui offers proposals for optimal production conditions and productivity improvements through joint prototyping.

In addition, Sekisui has decades of know-how in CPVC, PVC, and equipment. We will propose OEE (overall equipment efficiency) improvements based on our experience, taking a bird’s-eye view of the entire system.

We also make recommendations to customers regarding the shape of molds and screws, as well as production processes.

Extrusion simulation is used to analyze the condition of the extruder and die while checking the temperature and pressure. We also provide support for material design and production technology.

Sekisui Chemical offers the following CPVC compound products based on its superior technology.

“Durastream” – CPVC compound mainly used for hot and cold water supply piping

“Durastream α” – A tin-free CPVC compound that is specially designed to reduce environmental impact

“Durastream EX” – CPVC compound specialized for use in fire sprinkler piping

“Durastream HD” – CPVC compound specialized for industrial piping applications