PVC (Polyvinyl chloride resin) is a material that is essential for our daily life due to its high performance in terms of heat resistance, flame resistance and chemical resistance, as well as its excellent economic efficiency. On the other hand, CPVC (chlorinated polyvinyl chloride resin), a material that extends the characteristics of PVC, is used in various fields as a material that can adapt to harsh operating environments that PVC cannot withstand.

SEKISUI CHEMICAL Group has established CPVC production technology based on the technology it has cultivated, and further established a production company in Thailand in 2014 to supply high quality CPVC products globally. Today, the Group boasts one of the world’s leading shares in the CPVC sector.

Here we introduce how CPVC is produced, as well as its features and applications.

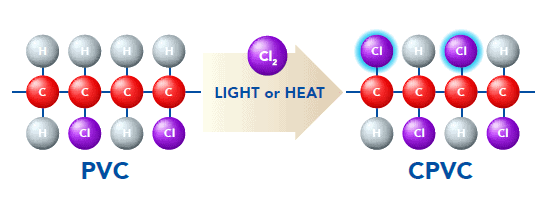

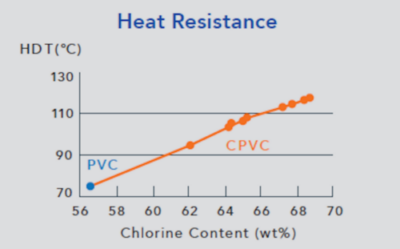

CPVC is produced through a chlorination process in which additional chlorine (Cl) is added to the manufactured PVC. The chlorine content of CPVC is 60-70%, whereas that of PVC in general is around 57%*1. When this is mixed with other pigments and additives to suit the purpose and processed, it becomes a CPVC compound. We offer the CPVC compound “Durastream” as our core product.

*1: Vinyl Environment Council, What is PVC: Modification methods and properties

https://www.vec.gr.jp/enbi/enbi2_5.html

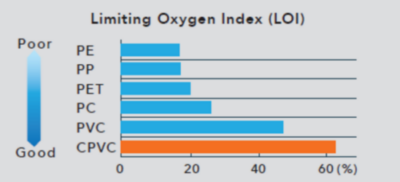

The advantage of CPVC is that it maintains the chemical resistance, electrical properties and mechanical strength of PVC, while significantly improving heat resistance and flame resistance.

Firstly, in terms of heat resistance, while the heat resistance temperature of general PVC is said to be around 70°C, CPVC improves the heat resistance temperature by 10-40°C to around 110°C. This makes it possible to use CPVC as piping through which high-temperature water or steam can pass.

For related pages on Heat Resistance, click here

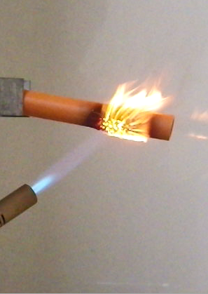

Secondly, in terms of flame resistance, CPVC is classified as 5VA*3, the highest level, while the flame resistance of general PVC is V0*2. This allows it to be used in construction areas with strict fire resistance requirements.

*2: V0 Self-extinguishing but burns relatively fast.

*3: 5VA Self-extinguishing and slowest burning rate.

CPVC is mainly used in harsh environments where PVC cannot be used. Examples include heat-resistant plastic piping in chemical and semiconductor plants, and fire sprinkler pipes and fittings. This is partly due to the fact that fire insurance often provides incentives for the use of CPVC.

For related pages on applications, click here

In regions with high average temperatures, CPVC may also be used in areas where PVC would normally be used, due to its superior heat resistance.

So far, the manufacturing process and characteristics of CPVC have been explained. In recent years, the use of CPVC has been increasing globally due to rising global construction demand.